Colonna’s has made significant investments to ensure its capabilities align with the diverse needs of its customers.

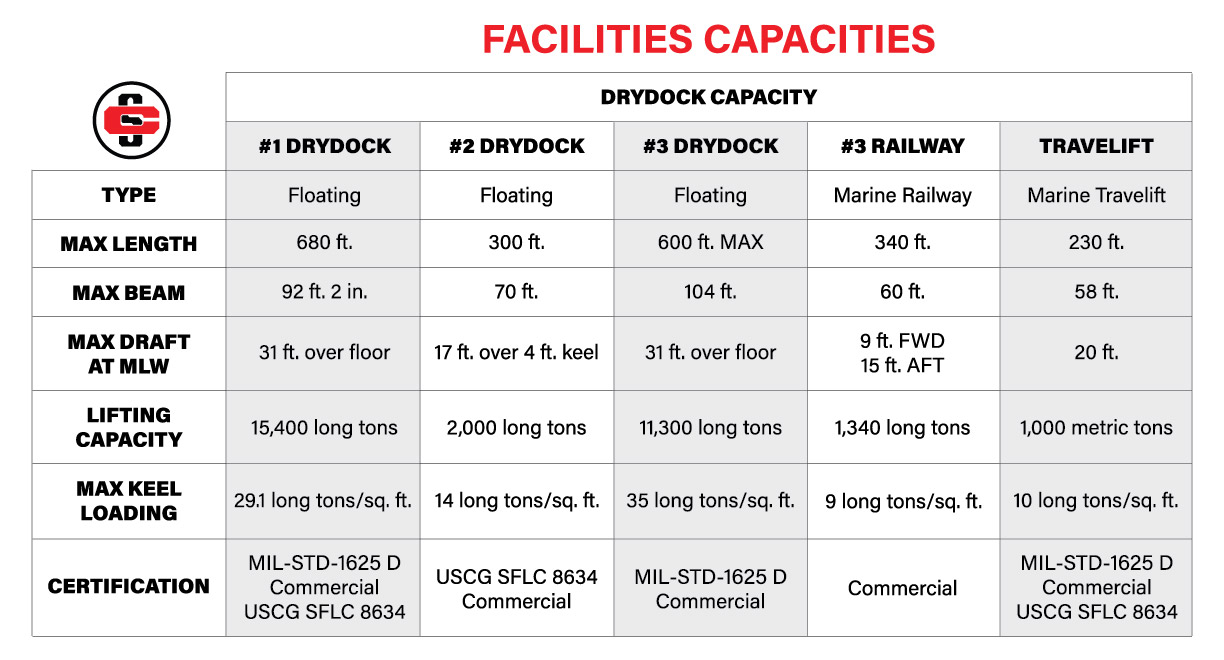

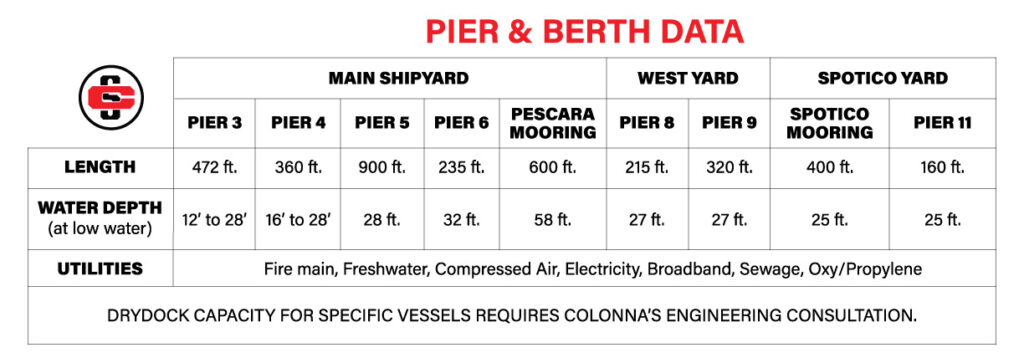

Located on 120 acres in Norfolk, VA, CS provides customers with an efficient and cost-effective layout of pier space, dry docks, railway, support shops, boat yards and administrative offices in a single and well-equipped facility. CS has full yard service utility distribution systems including steam, compressed air, compressed gas, potable water, cooling water and electrical power distribution of varying voltage, frequency and amperage. CS is also home to a 1,000 metric ton Marine Travelift.